Self-developed software platform

Station Controller

Station Control EMS

Station Controller is a locally deployed station-level software solution designed for high-performance operation. It facilitates millisecond-level control and monitoring communications with local devices and the power grid. Because Station Controller is technology-neutral, its deployment is not limited by device brand or application.

Key Features

Strength

Solar power generation/load forecastingAI

Operating stage

Applying self-developed physical and artificial intelligence models, we provide solar power generation and load forecasting services that can be quickly implemented for pre-meter and industrial and commercial energy storage projects.

Service Offerings

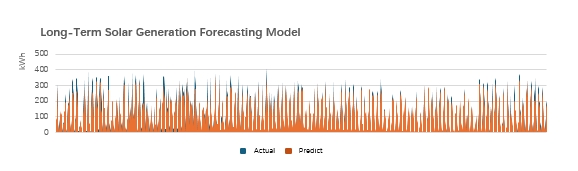

Cooperated with an automation control factory in Hsinchu to calculate the solar power generation data of the site for one year and compared it with the solar power generation time-sharing data (smart meter data) of the past year

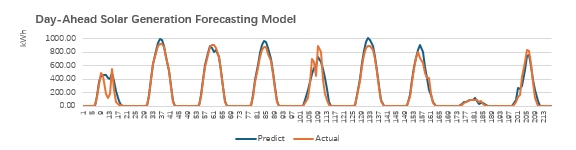

We have cooperated with a PV power station in Chiba Prefecture, Japan, and conducted POC testing with permission.

At 8 a.m. every day, the solar power generation model predicts the solar power generation every 30 minutes for the next two days and performs regression tests using actual power generation data.

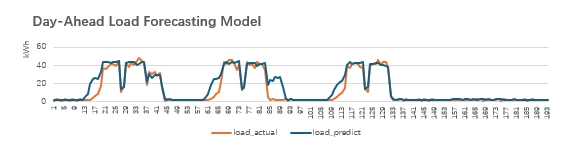

We conducted cooperative testing with multiple factories in Japan and, with their permission, used their load data from the past year to train the model, and then conducted a one-month POC test.

At 8 a.m. every day, we use the day-ahead load forecasting model to predict the load every 30 minutes for the next two days and perform regression testing using actual load data.